Robotic Deburring Cell

Experience gained in all types of casting makes siif the indisputable leader in this field.

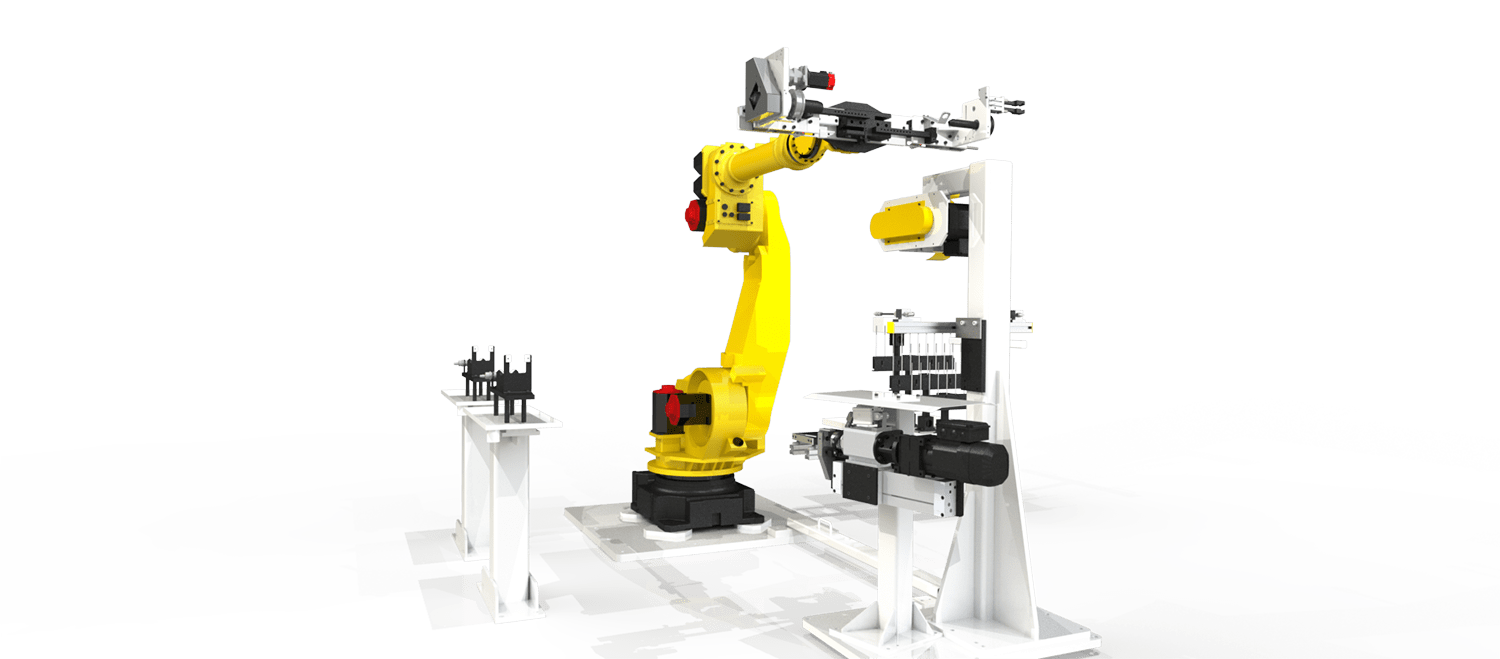

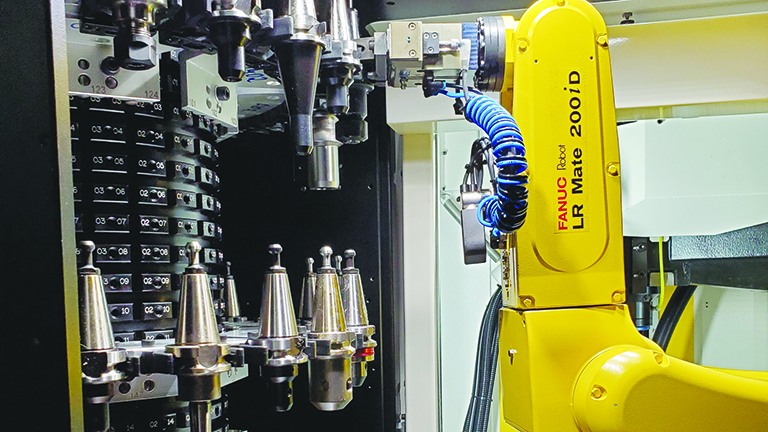

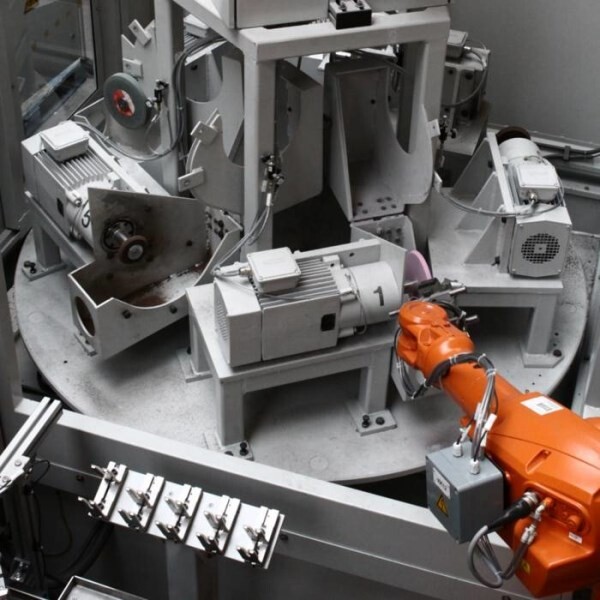

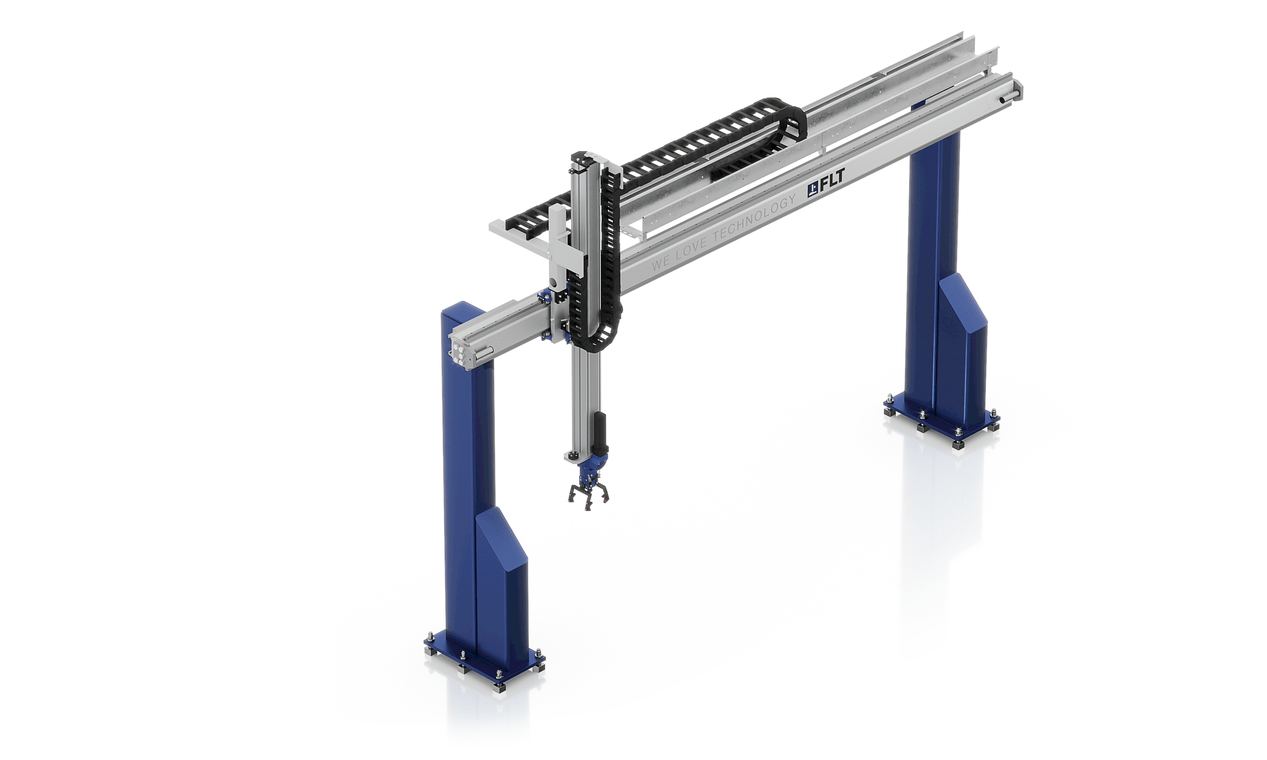

Robotic deburring cell. Mta robotic train system. The robotic deburring cell combines perfection performance and efficient processing in a single unit. For cast parts from aluminum brass or steel can be executed within a single deburring cell using sawing units. A six axis fanuc m 6i b robot is used in conjunction with two quick change end of arm grippers polishing wheels scathing tools pc based controls and a visual basic interface.

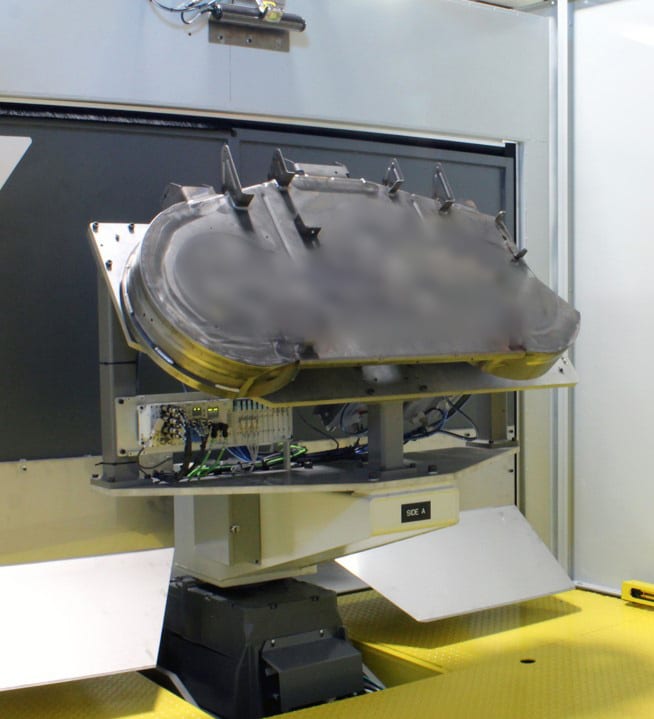

This robotic deburring cell processes jet engine component parts for an aerospace industry supplier. Watch this video to see how ati s compliant deburring tools increase safety and quality of material removal processes. This self contained compact cell can easily be transported to a new location using only a forklift. Large medium and small brush configurations.

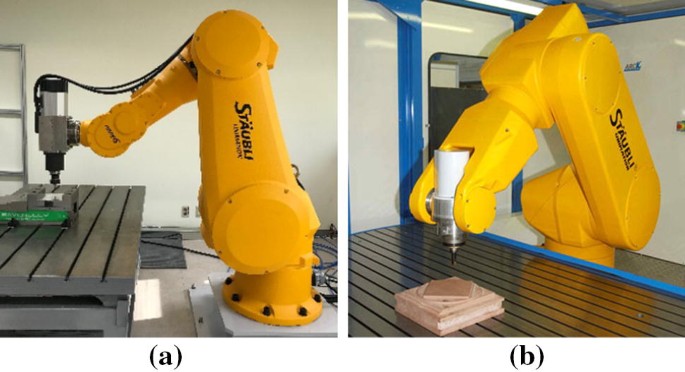

Removal of sprues or rising gates e g. Robotic deburring improves part quality because the robot can be programmed to each specific part and customized with the right eoat to apply the correct amount and type of pressure in each area. Mon fri 9am 5pm 732 791 5512 732 791 5512. 24 van dyke ave new brunswick nj 08901.

Robotic deburring cells robot development reliability and easy operation have naturally led siif to offer robotic finishing solutions for more. Long bottle brush for hard to reach locations. The sugino barriquan robotic deburring machine is an automated cell which features dual barriquan high speed spindles on an end of arm kuka robot designed to replace manual deburring in your factory. This robotic deburring cell from weldon solutions is optimally designed to create a small footprint on your shop floor measuring 54 x 54.

Tool drawer for automated tool change. Reliabotics all in one deburring cell equipped with co2 nozzle. In addition to the 6 axis robot there is a rotary positioning table to give full 7 axis capabilities for deburring the most complex of parts. A typical deburr tool used by robotics can sping between 18 000 25 000 rpm.

Chamfer tool and blow off.